THERMAL CHARGE® Heat Transfer Fluid - Oil & Gas

THERMAL CHARGE® Industrial fluids used in Oil & Gas applications are specially formulated to protect large, stationary diesel engines — including engines used in gas transmission compressor station service — against over-heating, winter freeze-ups and corrosion.

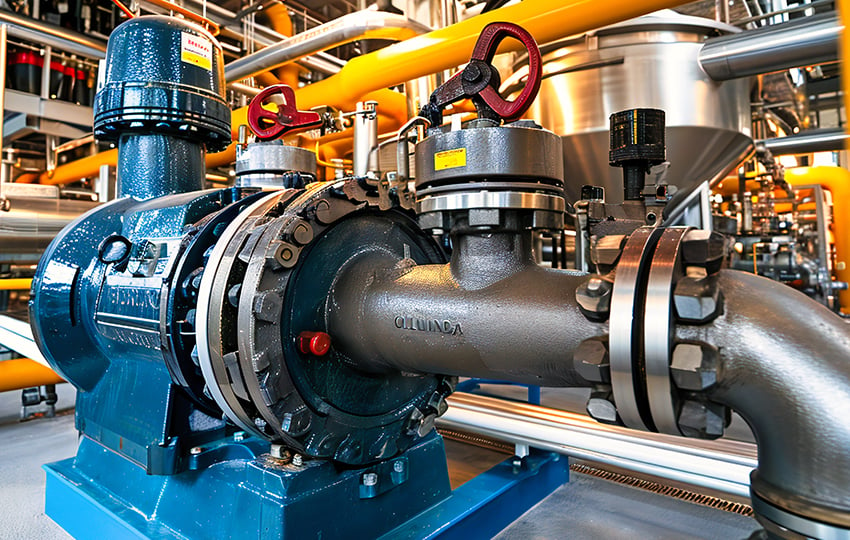

Stationary Engines

Stationary engines (SE) are used throughout the upstream, midstream and downstream process. The engines run various pipeline equipment which controls the optimal pressure, volume and temperature operating parameters for the oil and gas fluid to flow.

Explore THERMAL CHARGE® Industrial fluids Stationary Engines applications

-

THERMAL CHARGE® EGSE

Ethylene glycol-based coolant formulated with nitrite to protect against cylinder liner pitting, crevice corrosion and cavitation; Phosphate-free formula that meets ASTM 6210 requirements.

-

THERMAL CHARGE® PGSE

Propylene glycol-based coolant used where low toxicity fluids are required. It is formulated with nitrite to protect against cylinder liner pitting, crevice corrosion and cavitation; Phosphate-free formula that meets ASTM 6210 requirements.

-

THERMAL CHARGE® XL

Ethylene glycol-based coolant utilizing organic acid technology that delivers total system protection for 32,000+ hours. Borate, phosphate, nitrite and silicate-free formulation that meets ASTM 6210 requirements.

-

THERMAL CHARGE® Si-OAT

Thermal Charge® Original Equipment Technology™ Si-OAT 50/50 Prediluted Heat Transfer Fluid is a silicate-enhanced organic acid technology formula that matches the chemistry specified by stationary engine manufacturers.

-

THERMAL CHARGE® XL NOAT

Ethylene glycol-based coolant formulated with nitrited organic acid technology that delivers total system protection for 32,000+ hours; Phosphate-free formula that meets ASTM 6210 requirements.

Insulation Heating

Depending on the viscosity, pressure, temperature and volume of the liquid flowing through the pipeline, trace line heating or insulation may be required. Trace line systems run alongside of the oil and natural gas line to help with the flow.

Explore THERMAL CHARGE® Industrial fluids insulation heating applications

-

THERMAL CHARGE® EG

Inhibited ethylene glycol that protects system from corrosion, water pump cavitation and fouling. Most popular heat transfer fluid for non-food or beverage application.

-

THERMAL CHARGE® EGHD

Thermal Charge® EGHD heat transfer fluid is a heavy duty formulation of ethylene glycol and a specially formulated package of industrial corrosion inhibitors for use in closed systems with copper and other metal components, and for systems that require reliability in higher temperature operations.

-

THERMAL CHARGE® PGHD

Inhibited propylene glycol with a heavy-duty, robust inhibitor package for multi-metal applications requiring a less toxic fluid. Formulated to protect multi-metal surfaces, especially copper, as well as operate at higher temperatures.

Natural Gas Dehydration

All natural gas contains water. This water can cause corrosion, and reduced pipeline efficiency. Hydrates can also form blocking sections of the pipeline. Contract agreements implemented by gas transmission companies specify maximum allowable water content. This is usually 5 to 7 pounds of water per million standard cubic feet of gas.

The glycol regenerative type dehydration system uses Triethylene Glycol (TEG) to remove water form the natural gas.

Explore THERMAL CHARGE® Industrial fluids natural gas dehydration applications

-

THERMAL CHARGE® Inhibitor for TEG

Fortified with a superior state-of-the-art inhibitor package, Thermal Charge TEG is designed to prevent corrosion and retard glycol degradation which extends the fluid life and the service life of natural gas dehydration systems.

-

THERMAL CHARGE® Defoamer

A high concentrated inhibitor package for use with fully formulated Triethylene Glycol (TEG) based fluid used in natural gas dehydration systems.